Fuwa K-Hitch has partnered with Swinburne University and Ballarat consultancy Bisitecniks to design a fifth wheel testing laboratory in Melbourne. A Victorian first, it has already helped with the certification of Fuwa’s latest cast turntable model.

Until recently, testing the mechanical properties of a fifth wheel was a job that had to be carried out in Brisbane or Sydney, as the hydraulic equipment necessary is rare, expensive and complex to handle. For a long time, the two cities’ universities were the only institutions in the country allowing private enterprises access to such technology.

But with Swinburne University recently opening a $15 million ‘Smart Structures’ Laboratory in the Melbourne suburb of Hawthorn, local transport equipment expert Fuwa K-Hitch sensed an opportunity to finally bring some professional turntable testing capacity to the state of Victoria.

But with Swinburne University recently opening a $15 million ‘Smart Structures’ Laboratory in the Melbourne suburb of Hawthorn, local transport equipment expert Fuwa K-Hitch sensed an opportunity to finally bring some professional turntable testing capacity to the state of Victoria.

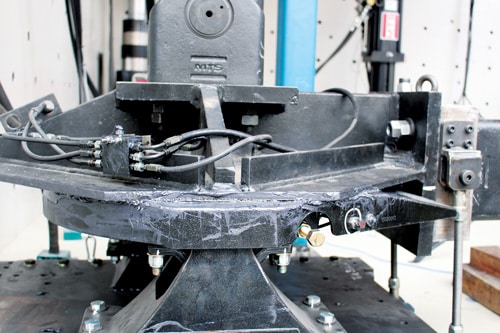

At the heart of Swinburne’s Hawthorn Laboratory is a Multi-Axis Substructure Testing (MAST) device, which is effectively able to simulate a fully-fledged earthquake. Driven by a large underground pump hidden beneath a metre of concrete, it inspired the team at Fuwa K-Hitch to utilise some of the force behind it to put the brand’s first-ever cast fifth wheel model to the test.

“While we knew the Smart Structures Laboratory was primarily built to test the integrity of architectural structures, we couldn’t ignore the potential use the lab’s giant hydraulics system may have for the testing of transport equipment,” says Markus Sidler, Product Manager at Fuwa K-Hitch and the driving force behind making professional turntable testing capacity available in Victoria.

To ensure the test would be carried out in accordance with the latest ADR standards, Fuwa K-Hitch also brought well-known Ballarat consultancy Bisitecniks on board. “We are a registered ADR test facility covering a wide range of ADRs,” says Bisitecniks’ Paul Walsh. “Our role was to ensure that the testing was conducted in accordance with the ADRs and included designing the equipment to interface with the Swinburne hydraulic apparatus. Together, we then went on to develop and execute the testing program.”

According to Paul, the ADRs require a new fifth wheel to endure a strenuous fatigue test that sees it oscillate some two million times over the course of a fortnight – equating to about a decade of constant usage. “It is quite a gruesome test that would have uncovered any weaknesses of the product immediately, but I have to say that Fuwa K-Hitch’s new cast fifth wheel performed exceptionally well,” he explains – adding that the paperwork for ADR approval is now on the way to Canberra.

In addition to the fatigue test carried out in Melbourne, Bisitecniks also performed a so-called overturning test at its facilities in Ballarat, as required by the ADRs. This test demonstrates how a new fifth wheel would cope with the lateral forces occurring during a roll-over scenario. Fuwa K-Hitch’s new model passed that test as well.

Paul adds, “It’s always exciting to see a new product become ready for volume production, but given this was the first ever fifth wheel tested locally in Victoria, it was a particularly special project for us to be involved in.”

With the approval process now on the home stretch, Fuwa K-Hitch is expecting the new cast fifth wheel to go on sale just in time for the Christmas season. “We are really looking forward to having a cast turntable in our portfolio,” says Sales & Product Specialist, Shane Harbridge. “The new model will be the lightweight alternative transport businesses operating on the eastern seaboard have been asking for in the past, but still come with a generous 200kN rating, which is ample for double and even triple work.”

Shane says the new, locally tested cast fifth wheel will come in six standard heights, with the option of further customising it if required. “While we feel that fabricated fifth wheels still have a place in the marketplace, the new cast model is more variable in terms of height as it is based on bolt-on feet, so there’s more room to play. What’s more, we included the secondary safety in the main handle for easy and safe single-hand operation – showing just how much thought went into the design.”

“After having it independently tested in Melbourne, we are extremely confident that our new cast fifth wheel will shake up the market once it goes on sale at the end of the year,” adds Markus. “The fact that we have invested in the creation of a local testing facility should be testament of how important the project was for us as an Australian business, but of course the transport community will have the last word when the product finally hits the road.

“For our part, we are extremely happy with the outcome and hope that we not only created a new fifth wheel for the line haul market, but brought back some highly coveted engineering know-how to Victoria that was only available in New South Wales and Queensland before. Even though the final product will be built in China, having created that kind of local legacy is something we are very proud of.”

Fast Fact: Fuwa K-Hitch’s new cast fifth wheel can boast bolt pattern feet for easy interchangability and has proven locking components that are the same as the current service parts in the fabricated range – ensuring parts identification and replacement is easy and cost effective. “We have taken already known and trusted know how and incorporated it into our new era of fifth wheels with further model expansion to come,” says National Sales Director, Chris Barrett.