Adversity is inevitable in a globalised economy, but axle and suspension expert Fuwa K-Hitch has proven that it doesn’t have to keep Australian transport businesses from finding success.

When Roman poet Horace famously stated that only adversity would reveal true genius, he most certainly didn’t have the transport equipment industry in mind. But in the face of a slowing economy and on-going political quarrel about the future of Australian manufacturing, his 2000-year-old observation is now seeing an unlikely revival in the axle and suspension market.

Melbourne business Fuwa K-Hitch has taken the age-old assertion as an inspiration to help transport businesses navigate a tough market by enabling them to achieve more productivity at a reduced cost base. “Times are tough, of that there is no doubt. The global economic downturn has spared no one and the transport industry in Australia is certainly feeling it,” says National Sales Manager, Chris Barrett.

“But the wheels have to keep turning, as they say. Existing trailers need to be kept on the road and running safely, and new equipment has to add much-needed productivity to our national fleet. At Fuwa K-Hitch, we want to play our part in that by providing transport businesses with high-quality, yet cost-effective equipment that can go the distance.”

He adds, “It’s all about empowering Australian transport businesses. It’s about giving them a great basis to work with and build on the ingenuity that has made them successful in the first place.”

While a shortfall in productivity growth is still weighing heavily on economic expansion in Australia, Chris says there is no reason to renounce faith in the notion of on-going growth and prosperity. “As part of the largest axle producer in the world and one of the biggest component suppliers in Australia, we have the right product range to help transport businesses of any size find a solution that is both economical and efficient. We believe there is opportunity in every challenge, and we have the size and scope to make a difference.”

Chris says Fuwa K-Hitch has every axle dimension covered, from general-purpose on-highway gear in the standard nine-13 tonne range, to extreme off-road equipment in the 20-tonne and beyond category. “On top of that, we will always go that extra mile to tailor a package that will suit the individual client, which is incredibly important in a time like today if you want to be able to add value,” he explains – adding that the global Fuwa network is actively supporting the Australian branch.

Chris says Fuwa K-Hitch has every axle dimension covered, from general-purpose on-highway gear in the standard nine-13 tonne range, to extreme off-road equipment in the 20-tonne and beyond category. “On top of that, we will always go that extra mile to tailor a package that will suit the individual client, which is incredibly important in a time like today if you want to be able to add value,” he explains – adding that the global Fuwa network is actively supporting the Australian branch.

“As one of the largest manufacturing businesses in our field, we have forged strategic alliances with a whole range of world-renowned companies, such as VDL Weweler in the Netherlands and WABCO in Belgium, just to name a few. That way we have quick access to the latest technology from China, Europe and North America and can react to any market movement in an instant. That flexibility is a powerful value proposition for our fleet clientele here in Australia, who trust in us to supply them with the best there is for the work they do.”

Chris says combining that flexibility with local thought-leadership is key to remaining competitive, especially in the face of adversity. But with transport margins tightening by the day, cost control is an ever-present issue. “The good thing of being part of the Fuwa Group is the volume we achieve, so we can be extremely price competitive. Price and quality don’t need to contradict each other once you reach certain economies of scale, and if you get both right, you have a strong business case.”

Despite the global footprint of the Chinese-based Fuwa corporation, Chris says Fuwa K-Hitch is still very much a local business. “We place huge value on holding stock locally to ensure the quickest possible turnaround times from order to supply, which means we react quickly to our customers’ requirements while reducing their own inventory costs and reliance,” he says. “We have also forged close relationships with many trailer manufacturers locally to offer them the best possible pricing and service.”

Combining stock availability and proven aftersales service with a global innovation and manufacturing network, Chris says Fuwa-Hitch has used a phase of economic uncertainty to create a toolset that will foster ingenuity within its customers’ businesses: “We work extremely hard behind the scenes, but at the end of the day, it’s all about our customers here in Australia. We want to enable them to look at any economic scenario and be positive about it, because they know they can rely on their equipment and focus on getting the job done safely.”

Fast Fact: With branches in Melbourne, Brisbane and Perth, as well as strong relationships with various OEMs and major aftermarket suppliers, Fuwa K-Hitch has built a national network spanning all of Australia.

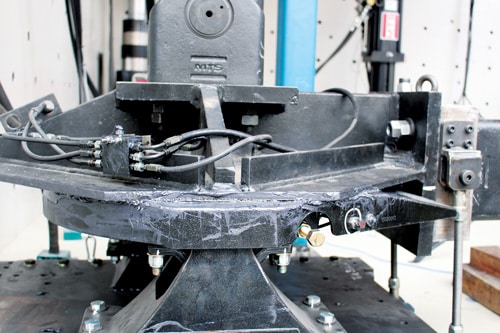

But with Swinburne University recently opening a $15 million ‘Smart Structures’ Laboratory in the Melbourne suburb of Hawthorn, local transport equipment expert Fuwa K-Hitch sensed an opportunity to finally bring some professional turntable testing capacity to the state of Victoria.

But with Swinburne University recently opening a $15 million ‘Smart Structures’ Laboratory in the Melbourne suburb of Hawthorn, local transport equipment expert Fuwa K-Hitch sensed an opportunity to finally bring some professional turntable testing capacity to the state of Victoria.