NGH Express has developed what it calls the ‘NGH Spec’, a set of particularly robust components and features that it knows can handle the gruelling route across the Nullabor. One that made the cut is the eLeg from Razor and Fuwa K-Hitch.

When Bryan Adams sang that “Only the Strong Survive” in 1987, his lyrics championed the value of mental strength in overcoming adversity. However, the concept also translates accurately to a physical level, especially when it comes to trailer building – for equipment to last, it has to be able to stand up to its environment. The sentiment rings true to those who travel on the coarse and uneven roads that cross the famous Nullarbor plains on the East-West route from Melbourne to Perth – a path that is the daily reality for NGH Express’s fleet of 11 trucks and 30 trailers.

Although the general freight fleet now has robust collection of equipment, Nathan Godfrey, Owner/Director of NGH Express, admits that he has gotten it wrong in the past. “We’ve certainly learnt a lot from buying the wrong stuff. It gets more complicated with trailers than with trucks, because there isn’t really a standard spec. So I took things into my own hands and developed what I call the ‘NGH Spec’,” Nathan says.

Although it took some trial and error to develop, the NGH Spec has become a very particular set of requirements that equipment must meet before it can be confidently added to the fleet. With the Nullarbor’s destructive roads in mind, Nathan decided early on that a priority focus for the NGH Spec had to be the strength of the components. “I like to build things tough,” he says. “Australia is a big country and we go from one side to the other, so our vehicles are travelling 7,000km week after week. I invest in equipment that will just keep going, because if you buy something cheap, then you have to expect to spend a lot of time fixing it.”

Nathan says it’s “really important” to have open conversations with trailer manufacturers and component suppliers to make sure equipment will be able to handle abuse from the roads or other environmental factors such as heat. “I go and see a trailer model and pick out all the weak points, then the manufacturer re-engineers it to match what I need. Topstart has been really good in that way – it builds whatever I want, however I want it,” Nathan says – revealing that the most recent trailer he has designed with Topstart is a 36-pallet double drop deck B-double delivered in December last year.

The new trailer set is a prime example of the NGH Spec, Nathan says, boasting tough floor to roof gates, thick outside curtains, a Teflon-topped turntable, 11-tonne pre-cambered axles with parallel bearings and his third set of eLeg automatic landing legs that are fitted to the A-trailer. “While I was re-designing the NGH Spec with Jimmy at Topstart, Colin Himmerman from Fuwa K-Hitch suggested I try the new automated landing leg that it was developing with Razor International. He’d previously suggested a sturdier axle to replace what I was using, which worked out really well, so I was confident to give the eLeg a try too,” Nathan explains.

As such, Colin says that NGH Express was one of the first companies in Australia to have the eLeg installed. “NGH was early off the mark. Before Nathan’s fleet we’d only supplied to about three or four others. Now, of course, the eLeg can be found on a rapidly growing number of significant fleets as standard fitment,” Colin says. “It is easier for the drivers to operate than a manual leg and they last a hell of a long time.”

Razor’s co-Managing Director, Geoff Watson, agrees that the eLeg holds up to the standards for the NGH Spec. “The eLeg has a robust, yet compact solid aluminium gearbox casing, and has undergone extensive testing to ensure it will be a valuable part of the NGH Express fleet,” he says – adding that the eLeg builds on Razor’s proven electronic landing leg technology.

The eLeg also does its part in preserving the strength of the NGH Express longhaul drivers, who already have enough fatigue management concerns without wearing themselves out manually operating landing legs. “As a business owner, you’ve got to think about workplace safety: anything to make life safer for the staff is a priority. In our case, that means removing the need to manually wind landing legs to protect drivers from back injuries,” Nathan says.

“The eLeg is definitely part of the future and it is good technology, so there’s no doubt that it will become part of the NGH Spec from now on.”

According to Colin, Nathan’s description reveals the main benefit of the eLeg, as it is all about improving OH&S. “It’s so easy to operate, and it’s not hard on the shoulders and arms of the operators because there is absolutely no labour involved. The drivers can save their energy for other, more important things,” he explains. “The eLeg is operated with a push button and simple high/low range gear lever, so the driver just has to hold the button and the legs will operate by way of the directional buttons.

“The leg incorporates internal sensors that trigger when the leg reaches the end of its stroke whilst retracting, or In the case of lowering the legs to the ground in high speed, when the load is imposed. To continue raising the trailer to the required fifth wheel height, you simply switch to low gear and push the directional button until the desired height is achieved. There’s no more manual work so it greatly reduces the chance of injury and costly claims.”

Taking care of his staff is incredibly important to Nathan, especially as the number of NGH Express employees continues to increase in alignment with the company’s growth. “Now I have about 14 staff members, including drivers, office staff and mechanics. The business has come a long way since I bought my first truck,” he says.

“Although I started from humble beginnings, I found a niche in the market and targeted it. Now, being dedicated to Perth linehaul has allowed me to grow my fleet and pick up work with some major companies. Next year, I’m anticipating adding two or three more trailer sets to the fleet, of course all built to the NGH Spec and complete with eLegs.”

Similarly to the NGH Express fleet, the trailer and component markets have evolved dramatically since the Canadian singer Bryan Adams released ‘Only the Strong Survive’ in the late 1980s. However, the requirement for hardwearing equipment is still the main constituent for the ‘NGH Spec’ and a widespread part of the Australian transport industry that isn’t likely to change.

Fast Fact: The majority of the trailers in the NGH Express fleet are pulled by Volvo FH prime movers, but Owner/Director Nathan Godfrey’s pride and joy is his fully customised 2010 Peterbilt 388, lovingly titled ‘Boneshaker’. For the second year in a row, it won the ‘Best Custom Truck’ award at the 2015 Castlemaine Rotary Truck Show. “It looks amazing and features paintwork from an artist at AIM Autographics. It represents a lot of money, time and effort, but it’s my dream. Everything is fully customised – it has everything I’ve ever wanted.”

Fast Fact: Displayed at the 2014 IAA Commercial Vehicles Show in Hanover, Germany, the first order of the fully automated landing leg was delivered to Vawdrey Australia in April last year. “This is a monumental feat, as it has taken Razor and Fuwa K-Hitch three years to commercialise the product,” says Razor’s co-Managing Director, Geoff Watson, who adds that the eLeg has the potential to ‘revolutionise the transport and logistic industry’.

Chris says Fuwa K-Hitch has every axle dimension covered, from general-purpose on-highway gear in the standard nine-13 tonne range, to extreme off-road equipment in the 20-tonne and beyond category. “On top of that, we will always go that extra mile to tailor a package that will suit the individual client, which is incredibly important in a time like today if you want to be able to add value,” he explains – adding that the global Fuwa network is actively supporting the Australian branch.

Chris says Fuwa K-Hitch has every axle dimension covered, from general-purpose on-highway gear in the standard nine-13 tonne range, to extreme off-road equipment in the 20-tonne and beyond category. “On top of that, we will always go that extra mile to tailor a package that will suit the individual client, which is incredibly important in a time like today if you want to be able to add value,” he explains – adding that the global Fuwa network is actively supporting the Australian branch.

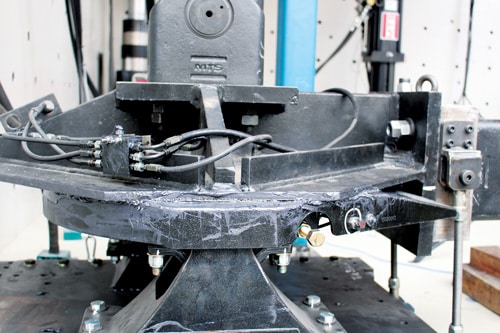

But with Swinburne University recently opening a $15 million ‘Smart Structures’ Laboratory in the Melbourne suburb of Hawthorn, local transport equipment expert Fuwa K-Hitch sensed an opportunity to finally bring some professional turntable testing capacity to the state of Victoria.

But with Swinburne University recently opening a $15 million ‘Smart Structures’ Laboratory in the Melbourne suburb of Hawthorn, local transport equipment expert Fuwa K-Hitch sensed an opportunity to finally bring some professional turntable testing capacity to the state of Victoria.