Since suspension expert Fuwa K-Hitch (FKH) became the authorised representative of dutch brand VDL Weweler in Australia; the partnership blossomed on all fronts with the Australian transport market now benefitting from VDL’s flagship product – the MBS suspension system.

Combining VDL Weweler’s Modular Bolt-On (MBS) suspension, the latest axle design by Chinese powerhouse Fuwa and a wealth of local expertise, FKH created

a realignment-free nine tonne axle and suspension solution that is multi-purpose, lightweight and low maintenance.

The new concept is currently being trialled in the Australian market, and initial feedback is more than promising, according to Chris Barrett of FKH.

“The industry will soon be able to benefit from this innovative product.

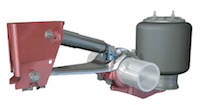

We are receiving excellent performance data across the board.” The key to success is the low number of components used in the MBS design. Chris explains, “The MBS suspension module only features one trailing arm, one shock absorber, one hanger bracket and two tail ends. And it is friendly on the axle because there is no welding on the axle.”

The unique forged spring steel trailing arm is a first in spring steel trailing arm design and the centrepiece of the MBS design. Held in position by a groove in the axle beam creating a keyway to lock the suspension, it can boast unique modularity in spring track, ride height and offset. “By removing the axle seat, there is no need for welding in the axle. This realignment-free, nine tonne non-welded suspension solution provides exceptional roll stiffness while putting less stress on the axle due to a unique tapered trailing arm with a wide clamping area,” says Chris. As the air suspension is clamped around the axle using three bolts, the need for U-bolts and U-bolt plates has been virtually eliminated. In addition, the 146mm Fuwa axle is based on the brand’s tried and proven one-piece forged axle beam with unitised bearings to reduce tare weight and maintenance. “The bolt technology has developed rapidly in the past,” says VDL Weweler’s Martin van Willigen, pointing out that welding can create a weak spot in any design. “The MBS design uses stress- resistant material that was not available a few years ago. A welded joint is the weak point of any construction.” As in all VDL Weweler’s air suspension systems, the MBS’ shock absorber uses high-temperature resistant Viton seals and acts as the stroke limiter, eliminating the need for check straps. With a system weight of just 128kg, the MBS air suspension is one of the lightest spring steel trailing arm suspensions on the market today.

Well-established in Europe – VDL’s market share in Europe is around 30 per cent – the MBS suspension is now on the rise in Australia and North America. For instance, US company AXN has recently joined the successful VDL Weweler/ Fuwa team to design a US version of the MBS, labelled MARS. The new product has been revealed at this year’s Mid-America Truck Show and demonstrated that the new concept is forging ahead an every continent.

In Australia, VDL Weweler can draw on 20 years of experience, but it was not until they entered an exclusive partnership with FKH in 2009 that their market share skyrocketed – not only in the trailer air suspension market, but also for truck pusher suspensions. “Prominent truck OEM DAF Trucks Australia has really helped VDL Weweler gain acceptance in the market,” says Chris. “Together with FKH, all doors are open to them. That’s what the market is signalising to us.”