VLD Weweler has now released its new range of modular Bolt-on® solutions (MBS) into the Australian market, including the new MBS Air Suspension with optional Bolt-on® Axle Lift, hanger bracket and bracing. available exclusively through its Australian distributor FUWA K-hitch, this suspension features less components for optimum durability and trouble-free maintenance.

MBS air suspension is a realignment-free nine tonne non-welded solution that has been developed completely in-house in accordance with VDL Weweler’s philosophy of creating products that are multi-purpose, light weight; and use minimal components and minimal maintenance.

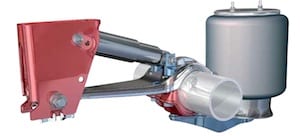

The air suspension is clamped around the axle using three bolts and is held in position by a groove in the axle beam, offering unique modularity in spring track, ride height and offset. This revolutionary groove was co- developed by VDL Weweler and Fuwa. VDL Weweler has been renowned for its expertise in the development and production of parabolic springs, air suspension systems, axle lift systems and special axles for over 80 years.

In 2001, the company was incorporated into the VDL Groep. The VDL Groep is an international industrial company focused on the development, production and sale of semi-finished products, buses and coaches and other finished products. It is a conglomerate of flexible, independent companies, each with its own specialty. The strength of the VDL Groep lies in the mutual co-operation between these companies. Since its founding in 1953, the VDL Group has grown to include 79 operating companies, spread over 16 countries, with more than 7400 employees.

VDL Weweler also has over 20 years of experience in Australia, thus resulting in an exclusive distributorship with Fuwa K-Hitch in 2009. “Fuwa is a strategic partner worldwide and therefore Fuwa K-Hitch was a logical next step. Fuwa K-Hitch does a superb job and has increased the market share of VDL Weweler enormously. This strong relationship has resulted in a unique suspension and axle combination,” says Martin van Willigen of VDL Weweler in the Netherlands.

VDL Weweler prides itself on developing systems that are robust and deliver reliability and cost-effective operation for on- highway applications as well as in the most demanding operating environments, such as those found in Australia – and the MBS air suspension is no exception. The company’s ISO-certified manufacturing facilities in Apeldoorn (The Netherlands) and Poperinge (Belgium) are highly automated, with robotics playing an important role in cost-effective and reliable production.

Using just one type of shock absorber, hanger bracket, forged spring steel trailing arm, two completely interchangeable airbags and two different tail ends, MBS accommodates a comprehensive range of ride heights ranging from 210mm to 410mm, and offsets for almost any trailer application. By simply releasing a single bolt, both tail ends can be given offsets of 0, 25, 50, 65, and 90mm in either direction, eliminating the need for a left and right version.

The unique forged spring steel trailing arm that eliminates the need for U-bolts and U-bolt plates, is a first in spring steel trailing arm design. The tapered trailing arm profile with its wider clamping area and small diameter maintenance-free bushing provides unequalled roll stiffness while putting less stress on the axle, in turn maximising the service life. As in all VDL Weweler’s air suspension systems, the shock absorber uses high- temperature resistant Viton® seals and acts as the stroke limiter, eliminating the need for check straps. With a system weight of just 128kg, the MBS air suspension is one of the lightest spring steel trailing arm suspensions on the market today.